Successful from medical technology to cosmetics to disinfection

terraplasma GmbH is considered a pioneer in the development of applications with cold plasma and has achieved significant successes regarding the market readiness of this technology since its foundation in 2011. Through close cooperation with partner companies, innovative products have been developed and brought to market that are used in various areas.

- The medical device plasma care was developed with terraplasma medical GmbH. This portable device uses cold plasma to promote wound healing and reduce germs in acute and chronic wounds. As the first mobile cold plasma device for wound healing, the compact plasma care is an innovative solution for patients and healthcare professionals.

- Together with hyped about science GmbH, terraplasma developed the compact consumer device Phlas. This uses cold plasma technology to regenerate acne-prone skin, reduce redness and care for skin and pimple marks without irritating ingredients. Phlas is gentle thanks to plasma, free of heat or harsh chemicals, making it suitable for all skin types. The development of this consumer device is based on extensive experience in device development in the fields of medicine, household appliance and laboratory equipment and has been integrated into a compact and elegant design.

- In cooperation with KIMETEC GmbH, the PlasmaEgg was created, a mobile disinfection device that uses cold plasma technology to disinfect the surfaces of a wide variety of objects effectively and in an environmentally friendly way. It offers a chemical- and heat-free alternative to conventional disinfection methods and is versatile in the laboratory and medical environment due to its slim design.

These success stories illustrate the wide range of applications of cold plasma technology and terraplasma GmbH’s commitment to developing innovative and sustainable solutions to current challenges. Now the company is focusing on the topic of water treatment with cold plasma to make its contribution to sustainable management and sustainable water management.

Cold plasma as a sustainable technology for water treatment

Cold plasma has the potential to revolutionize water treatment, as this technology offers decisive advantages over conventional disinfection methods such as UV, chlorine, ozone or reverse osmosis. Cold plasma works with highly reactive species directly in the water. This efficiently eliminates bacteria, viruses, organic impurities, pollutants and trace substances – without the use of additional chemicals or residues.

- Compared to chlorine, there are no harmful by-products or changes in taste

- Cold plasma is effective against UV radiation in the entire water volume, not only on the surface. In addition, there is no shadow effect.

- Unlike ozone, it requires only a comparatively low energy requirement and eliminates the need for oxygen.

- and unlike reverse osmosis, plasma technology works without high pressures or special membranes in the system, and the natural mineral composition of the water is preserved.

In addition, cold plasma works very sustainably and energy-efficiently – current prototypes basically generate no waste materials and require only a fraction of the energy as UV-based solutions, for example. With this innovative technology, terraplasma is already setting new standards for environmentally friendly, safe and scalable water treatment.

Successful pilot projects pave the way for cold plasma water treatment

A pilot project for drinking water treatment launched two years ago is investigating the use of cold plasma to reduce contamination by PFAS (per- and polyfluorinated alkyl substances). After initial tests with lightly contaminated water, further investigations were carried out in a more severely affected region. Initial tests with water samples from this PFAS hotspot showed a reduction of PFAS by up to 30% using cold plasma technology that has not yet been optimized. The results show that each water source has its own unique challenges and that new technologies are needed to sustainably complement existing processes.

In another pilot project with a specialist company for the treatment of industrial wastewater from the automotive production sector, the COD value (chemical oxygen demand) could be measurably reduced thanks to cold plasma. Here, too, non-optimized cold plasma technology was used – greater efficiency will be achieved by adapting the technology to the specific application.

The knowledge gained from the pilot projects will be incorporated into further research at terraplasma to develop sustainable and market-ready solutions for water treatment with cold plasma together with partners.

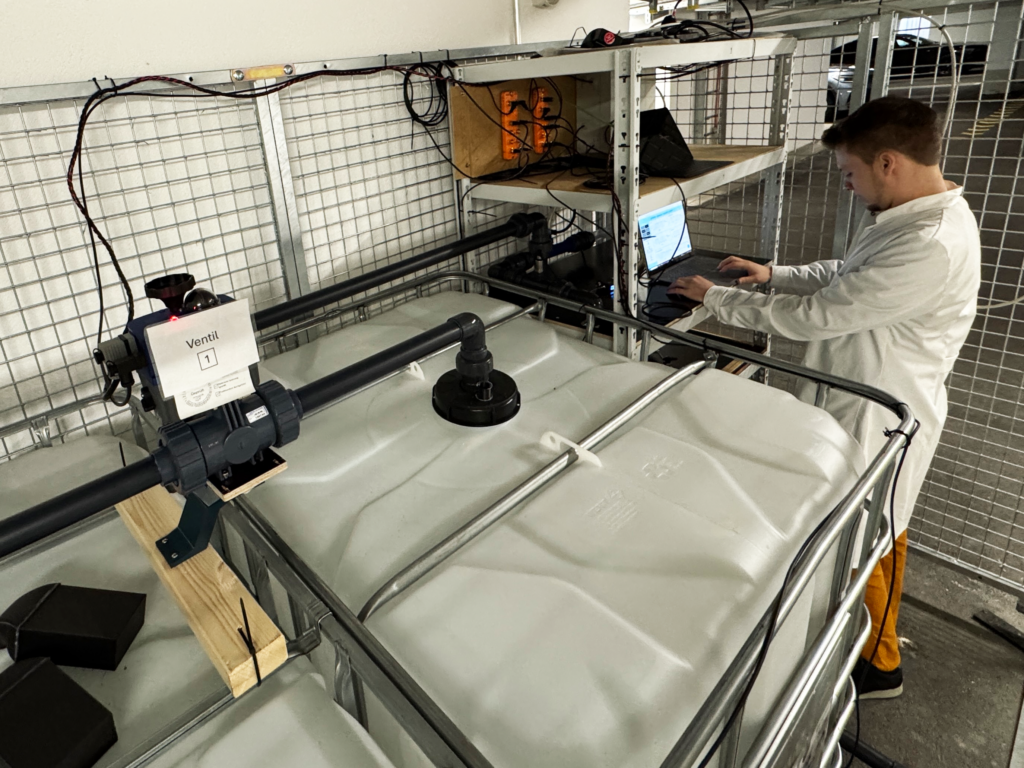

Scaling cold plasma technology for water treatment with greater throughput

The next development goal for terraplasma is to test an industrial-scale system with a flow rate of about 100 l/min based on the successful small setups with cold plasma. The development team is working with a large demonstrator to achieve this scale: “Plasma Pure Water” is the name of this prototype for water treatment on an industrial scale. As a special feature, terraplasma is also planning to develop an automated, dynamic adaptation of the plasma power for water treatment in real time to the changing load of the water under the term “Plasma Aqua Intelligence (PAI)”.