Background: Chemical-free disinfection as part of the green economy

In view of the EU Chemicals Strategy for Sustainability(CSS) and the associated demand for a reduction in the use of environmentally harmful substances, alternative disinfection methods are becoming increasingly important. Conventional chemical disinfectants – including biocides such as triclosan – are not only associated with risks for the environment and water, but also promote the development of resistance in pathogenic microorganisms.

The technology developed therefore relies specifically on plasma-activated mist – a mixture of reactive species that is generated by combining cold atmospheric plasma (Cold Atmospheric Plasma CAP) and micro-fine water mist. This method enables material-friendly, residue-free and effective inactivation of microbial contamination – without the use of conventional chemicals.

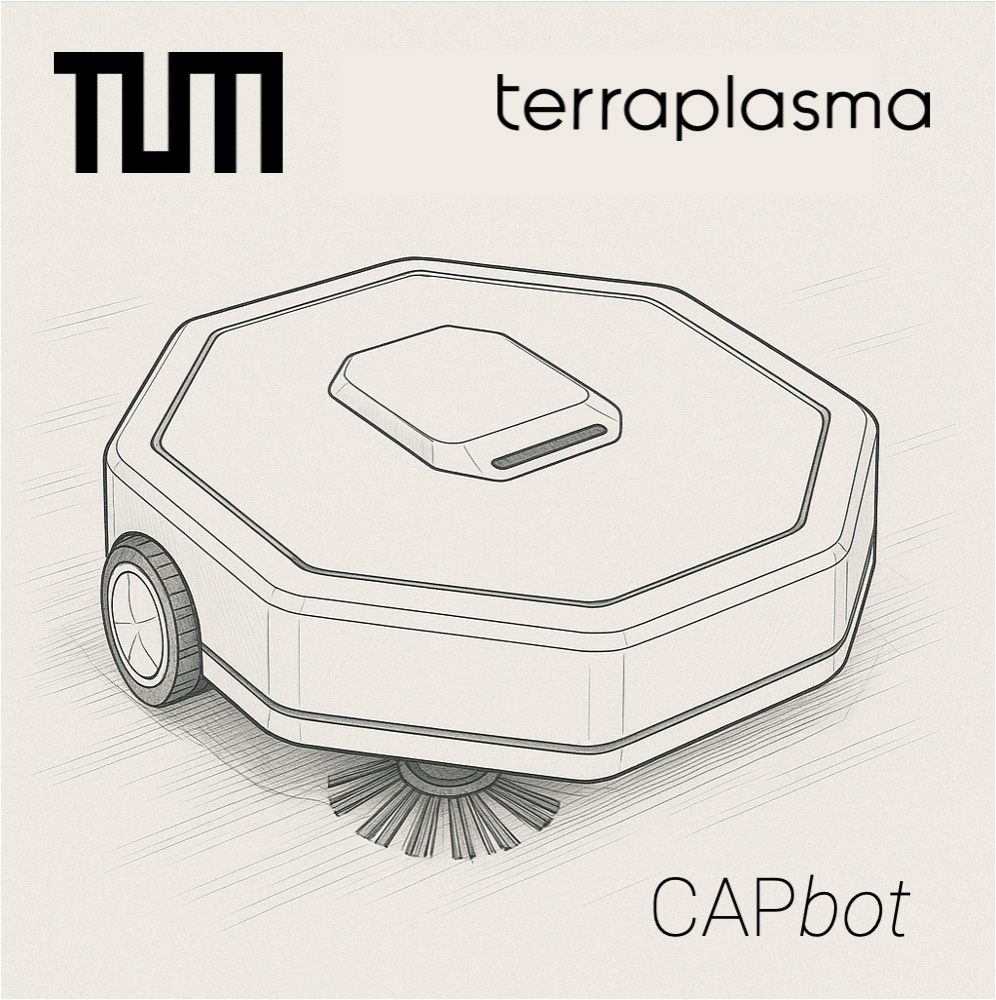

Technological approach: plasma mist in automated use

The basic principles for generating plasma mist developed as part of a previous DBU project in 2024 are now being transferred to a mobile robot platform. Preliminary tests have shown that the plasma-water mist combination can achieve a bacterial germ reduction of up to 5 log levels (99.999%) in just 5-10 seconds – without significant material degradation.

Of particular scientific relevance is the fact that the plasma species are not only effective against bacteria, but also against viruses and fungi – with a very low probability of resistance formation, as observed with chemical biocides.

The cleaning robot has a modular prototype design and combines navigation intelligence with adaptive dosing of the plasma mist. The solution is scalable and is also conceivable for larger areas on an industrial scale in the future.

Outlook: Plasma application in a hygiene-critical environment

“Our research shows that plasma-activated fog is not only an effective alternative to chemical disinfectants, but can also be an important building block for sustainable, safe hygiene concepts,” emphasizes Dr. Julia Zimmermann, Managing Director of terraplasma GmbH. “Our approach offers enormous potential, particularly in areas with an increased risk of infection and a simultaneous need for sustainability.”

The findings from the project will then be transferred to further development steps, field tests and possible product approval.