Surface treatment with Cold Plasma

Procure as you wish.

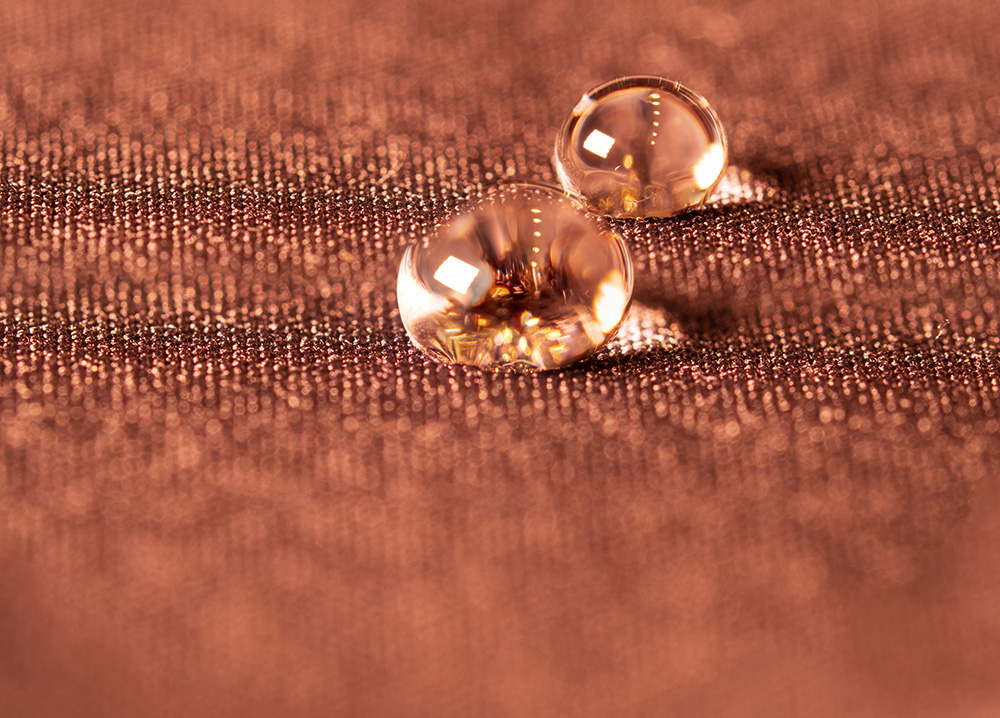

In surface treatment with Cold Plasma, the plasma is applied to the surface of materials in order to change their properties. This serves to improve adhesion, change the surface roughness or create new functional groups on the surface. This makes painting, for example, easier and more efficient – and without any additional chemicals.

Change without extra chemicals

In many cases, cold plasma surface treatment can be a more effective and environmentally friendly alternative to conventional chemical treatments.

The use of cold plasma treatment of surfaces has been explored in a variety of fields, including materials science, electronics and biomedicine. In the field of materials science, surface treatment has been used to improve the adhesion of coatings, increase the wear resistance of materials, and alter the surface energy of materials to make them more hydrophobic or hydrophilic.

In electronics, surface treatment has been used to improve the adhesion of thin films, to create high-performance surfaces for electronic devices and to create nanostructures for photonic applications. In biomedicine, surface treatment has been used to sterilise medical devices and improve the biocompatibility of implant materials.

Your company and Cold Plasma

Find exactly the right application from the variety of possibilities. Individually for your product. Talk to us about the possibilities of using cold plasma for you!