They are not visible to the naked eye and yet they “sit” almost everywhere: microorganisms, i.e. viruses, bacteria and fungi, are found on almost all freely accessible surfaces – because under normal conditions nowhere is “really clean” (i.e. germ-free). The good news: most microorganisms are not dangerous for a healthy person. But germ-contaminated surfaces can become a health risk – especially for people with previous illnesses and a weak immune system.

Appropriate disinfection kills the microorganisms on the surface and prevents them from being carried over. Microorganisms can survive and remain infectious on different surfaces for different lengths of time – this depends on the characteristic properties of the microorganisms. The nature of the surface on which the microorganisms are located, and the environmental conditions (temperature and humidity) also have an influence.

Chemistry, heat and radiation were yesterday

Disinfection is an essential part of antiseptic (germ-free) work and means “putting dead or living material in a condition that it can no longer infect”. Various methods can be used for disinfection, with “classic” chemical disinfectants such as hydrogen peroxide, chlorine, ozone, aldehydes, alcohols or iodine playing a major role to date, as well as disinfection by heat or radiation.

However, chemical disinfectants have many disadvantages – they are not only toxic to humans or even carcinogenic, but also generate resistance if used improperly, especially if the concentration of active ingredient and exposure time and thus the germ reduction factor are too low. Chemical disinfectants also cause permanent damage to human skin and some substances can also irritate human mucous membranes. Some chemicals also attack surfaces made of metal, plastic or natural materials and therefore cannot be used to disinfect these surfaces.

The many negative effects on the environment caused by chemical disinfection should also not be neglected: First, the chemicals must be produced, stored and finally transported to the place of use, which is energy intensive. If they are not used properly or disposed of properly, they get into rivers or sewage treatment plants and disturb the important interaction of many bacterial species there, which e.g., reduces the cleaning effect (in clarification tanks or water bodies). In addition, many disinfectants also have an ecotoxic effect on water bodies.

Most microorganisms can also be killed by heating at sufficiently high temperatures. However, this method is not very suitable for freely accessible surfaces, as it is difficult to direct the heat precisely and evenly onto a surface without leaving permanent damage. In the case of disinfection by irradiation (UVC light or gamma rays), the treatment of surfaces is also difficult, since “open” disinfection sources would have to be used here, which are also harmful to people’s health if used improperly.

Cold plasma is the future of disinfection

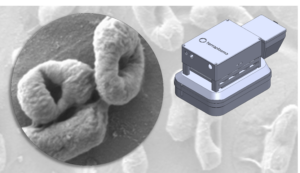

The use of cold plasma (or low-temperature plasma) is a new type of disinfection technology that can kill even antibiotic-resistant microorganisms not only on surfaces but even through clothing at room temperature in a time-saving manner. This makes cold plasma suitable for disinfecting air, surfaces, objects, hand disinfection, but also for treating poorly healing chronic wounds.

The solution approach in this research project is the development of a sustainable, environmentally friendly, and scalable technology that allows the simple and targeted generation of disinfecting plasma mist that is suitable for the highly effective reduction of germs on openly accessible surfaces. The first preliminary tests were so successful that the team from the Chair for Medical Materials and Implants (MMI) and terraplasma is optimistic that they will achieve or even exceed the individual sub-goals. This includes the development of an improved plasma source that also ignites in a humid environment, the optimization of the nebulization and the energy supply of the plasma system, the development of a functional prototype and the detailed investigation of the disinfecting effect of the generated plasma mist on various microorganisms as well as research into possible side effects of the Plasma mist treatment on various materials.

The research project called “Plasma-activated fog for the disinfection of surfaces” is funded by the German Federal Foundation for the Environment (DBU) and was approved on March 20, 2023. The operational start took place on April 17, 2023, with a term of almost 14 months and a total volume of around €300,000. The project is being carried out between MMI and terraplasma GmbH.